Lines and equipment for feed production GTO

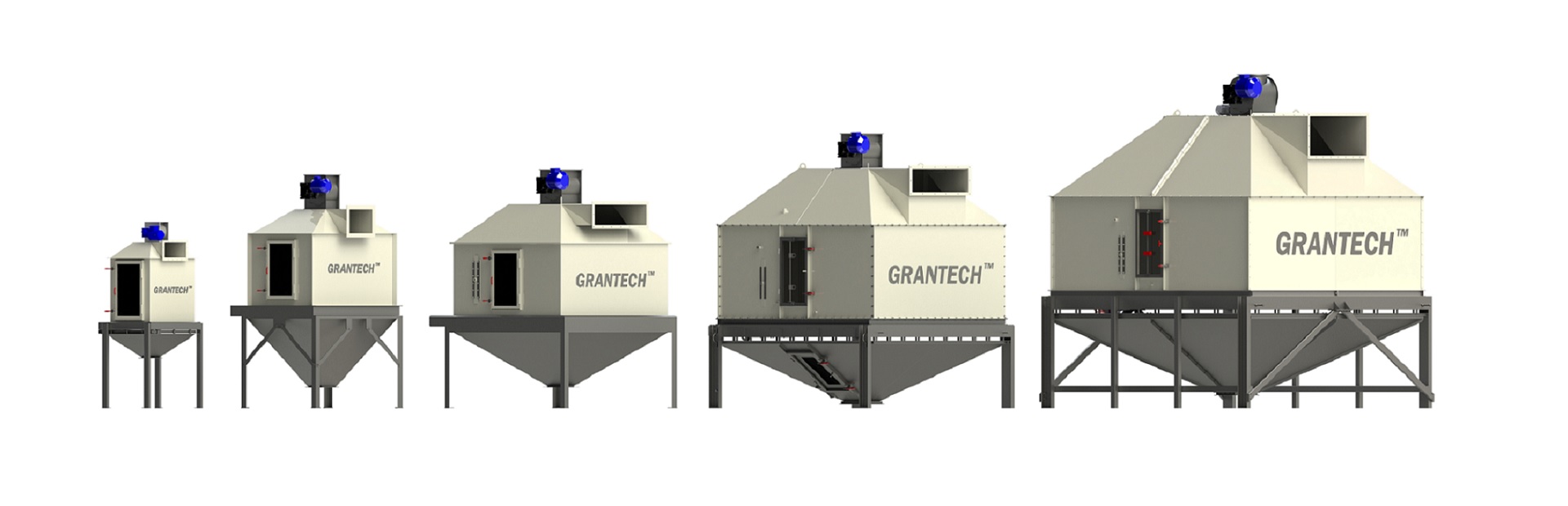

The countercurrent cooler is designed for cooling the pellets coming from the pellet mill. It consists of the case, ventilator and cyclone with the air-lock gate.

The pellets are continuously discharged by gravity from the pellet mill into the cooler and even distributed along the cooler area, to this effect the special distributor is installed in its upper part. The air-lock gate driven by the motor-reducer is placed in order to prevent the air suction through the charging opening.

Lines and equipment for feed production GTO

The countercurrent cooler is designed for cooling the pellets coming from the pellet mill. It consists of the case, ventilator and cyclone with the air-lock gate.

The pellets are continuously discharged by gravity from the pellet mill into the cooler and even distributed along the cooler area, to this effect the special distributor is installed in its upper part. The air-lock gate driven by the motor-reducer is placed in order to prevent the air suction through the charging opening.

Advantages of GTO cooler:

- high performance and uniformity of pellets cooling;

- elimination of the heat stroke effect;

- minimum mechanical impact on the fragile heated pellets during cooling;

- designs of the cooling area and discharging device with self-cleaning of the moving components prevent from forming of the clogging zones and the pellets chocking-up. This results in the improving of the hygiene and sanitary parameters of the equipment and the cooled product;

- low power consumption and maintenance costs.