GTDRM Hammer Mills are specially designed by ICK Group for fine milling of light materials:

- wastes from agro-industrial complexes (straw, hay) coming from GTIS TM GRANTECH Straw Chopper;

- wood residues (chips, sawdust) after chipping or wood-shaving machines;

- sunflower, rice, millet husks etc.;

- other kinds of raw material.

GTDRM Hammer Mills can be used in live stock sector for mixed feed milling as well.

Raw material particles size should be up to 50 mm and of humidity no more than 14%

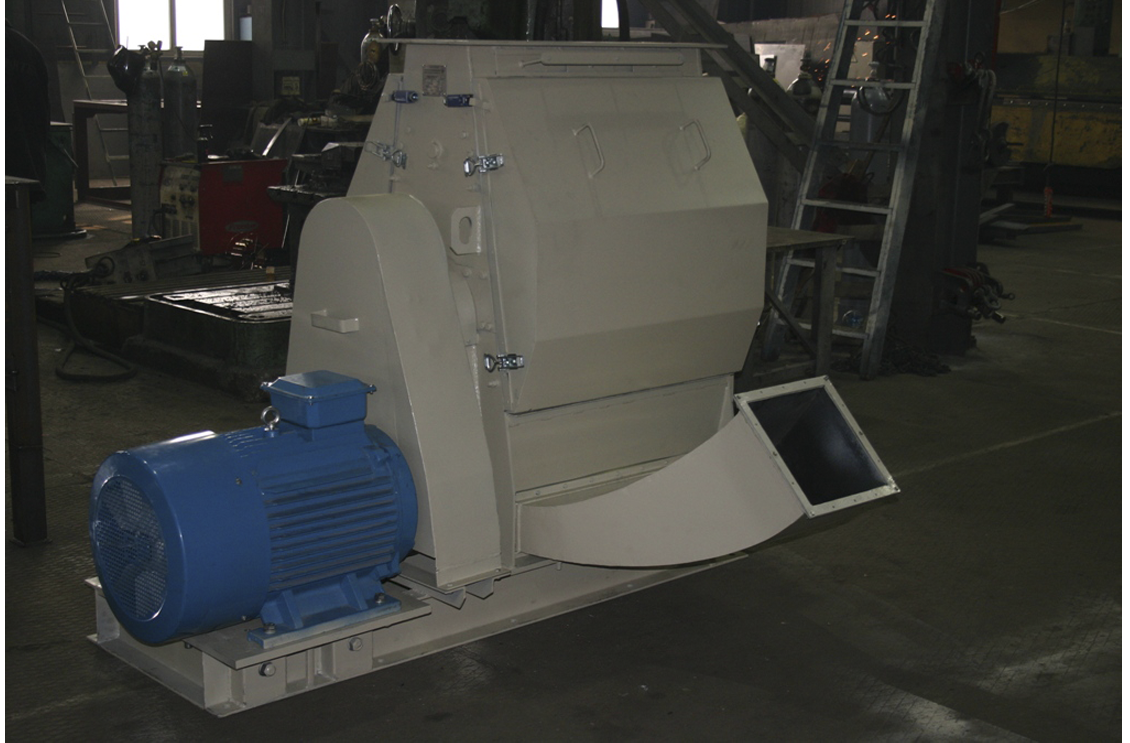

Hammer mills GTDRM

GTDRM Hammer Mills are specially designed by ICK Group for fine milling of light materials:

- wastes from agro-industrial complexes (straw, hay) coming from GTIS TM GRANTECH Straw Chopper;

- wood residues (chips, sawdust) after chipping or wood-shaving machines;

- sunflower, rice, millet husks etc.;

- other kinds of raw material.

GTDRM Hammer Mills can be used in live stock sector for mixed feed milling as well.

Raw material particles size should be up to 50 mm and of humidity no more than 14%

Advantages:

- high productivity with relatively low energy consumption;

- hammer mill adaptation to various raw materials with adjust to their characteristics;

- large area of screen surface and loading door;

- simplicity and compactness of design;

- low current cost, quick change of screens and hammers;

- longevity. Carefully balanced rotor and possibility of drum reverse rotation;

- high reliability and safe operation.

* Hammer mill productivity depends on kind of raw material, its physical characteristics, particles size.

The particles size of the milled raw material in the given range depends on the used screens and can be 3-6 mm.

The larger screen holes diameter and less humidity, the higher productivity.

Screen holes diameter is agreed with the customer.