GTL-304D Minicomplex is designed for production of fuel pellets from preliminary prepared components of woodworking residues, straw grain, sunflower husks and other energy biomass of plant origin.

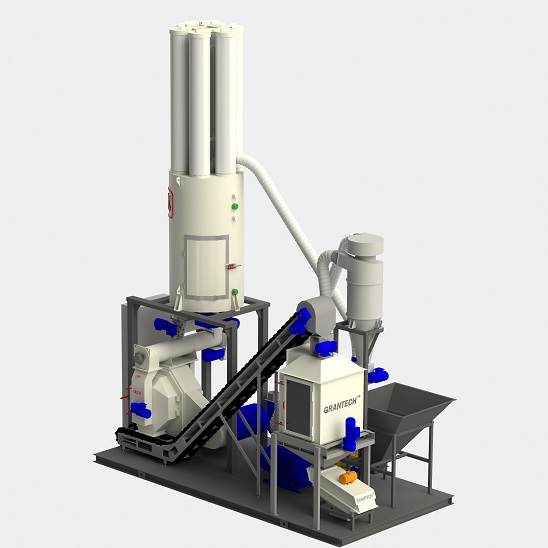

Minicomplex fpr pelletizing of biofuel in the base set consists of: feed funnel, mill with pneumatic loading, storage bin, dosing device, mixer, GT-304D pellet mill, the belt conveyer with scrapers, countercurrent cooler GTО-7х8, sieving machine GTP-1, Cyclone, ventilator, the automatic control system, filter block, one-piece frame.

GTL-304D Minicomplexes

GTL-304D Minicomplex is designed for production of fuel pellets from preliminary prepared components of woodworking residues, straw grain, sunflower husks and other energy biomass of plant origin.

Minicomplex fpr pelletizing of biofuel in the base set consists of: feed funnel, mill with pneumatic loading, storage bin, dosing device, mixer, GT-304D pellet mill, the belt conveyer with scrapers, countercurrent cooler GTО-7х8, sieving machine GTP-1, Cyclone, ventilator, the automatic control system, filter block, one-piece frame.

GTL-304D Minicomplex can operate at the temperature range from +50C up to 400C and relative humidity up to 80% when using qualitative accessories and materials.

For GTL-304D Minicomplex operation the following should be provided:

- power supply 380 V, 50 Hz, 90 kW;

- compressed air pressure 4-6 bars, 250 l/min;

- dry saturated steam pressure 3 bars.

- raw material preparation and separation from foreign materials;

- wet raw material drying (GTSK-0,6/4 Drying complex);

- accounting, packaging and storage of finished product.